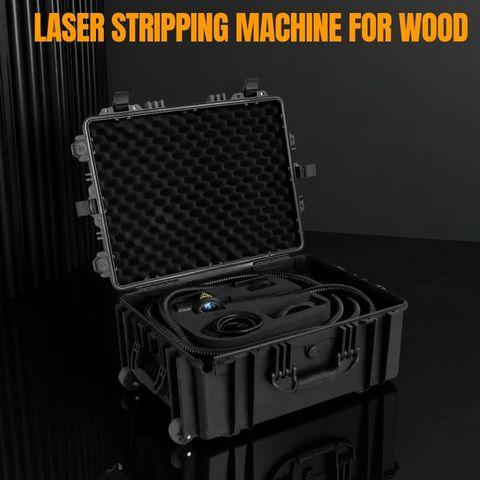

Elevate Your Wood Restoration Projects with a Laser Stripping Machine for Wood

Wood restoration is an art that requires precision, patience, and the right tools. Traditional stripping techniques often rely on sanding, scraping, and chemicals that can harm both the material and the environment. In today’s modern workspace, efficiency and accuracy matter more than ever—and that is where the laser stripping machine for wood takes the lead as a game-changing solution for craftsmen, restoration experts, furniture manufacturers, and industrial users.

This innovative system removes paint, varnish, resin, soot, and surface contaminants using non-contact laser beam technology. Instead of grinding away the wood surface or soaking it in toxic solvents, you get a clean, controlled stripping process that preserves natural texture and grain quality. The result? A smooth, renewed surface ready for staining, polishing, or refinishing—without material damage or fiber loss.

One of the standout advantages of a laser stripping machine for wood is consistency. Manual sanding can leave uneven patches, while chemical strippers require repeated application and careful cleanup. Laser technology delivers uniform removal across flat, curved, or detailed carved surfaces. Antique furniture, doors, beams, flooring, or large timber structures can be restored with remarkable clarity and precision.

Another major benefit is cleanliness and sustainability. Laser stripping produces minimal dust and eliminates chemical fumes entirely, making it a safer choice for both professionals and the environment. Workshops remain cleaner, air quality improves, and there’s no hazardous waste to dispose of. Workers save time, effort, and occupational risk while increasing output quality and overall efficiency.

The technology is designed for versatility—from delicate museum-grade artifacts to heavy-duty industrial beams. Adjustable laser power allows operators to fine-tune stripping intensity based on the wood type and coating thickness. Whether dealing with stubborn multi-layered paint or lightly weathered surfaces, users maintain perfect control throughout the process. This balance of power and softness is what puts laser stripping ahead of traditional restoration tools.

Speed is another factor that professionals appreciate. Jobs that once took days of sanding can be completed in a fraction of the time. Production workflows accelerate, labor cost drops, and customer satisfaction grows. Businesses adopting laser systems position themselves at the forefront of modern wood treatment and restoration services.

Investing in this machine is not just a purchase—it’s an upgrade to your production potential. The demand for clean, chemical-free finishing methods is rising across construction, woodworking, and heritage preservation industries. Adopting this technology enhances service quality, boosts brand credibility, and creates opportunities for premium-tier projects.

If you are ready to streamline your restoration process, protect material integrity, and produce visually refined results with minimum effort, the laser stripping machine for wood stands as a powerful choice. Explore specifications, features, and usage applications through the official link to take your work to a more professional and profitable level.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness