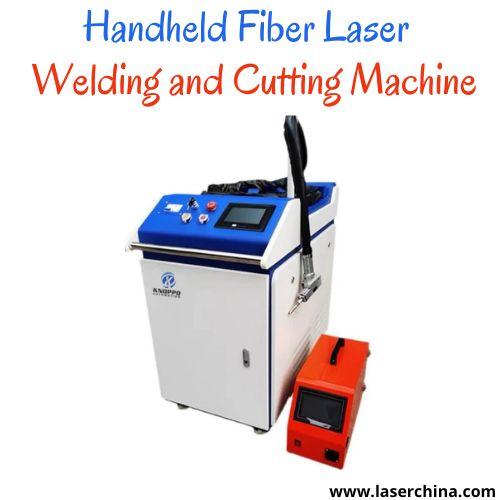

Handheld Fiber Laser Welding and Cutting Machine for Precise Metal Fabrication in Modern Workshops

The handheld fiber laser welding and cutting machine is becoming a core tool in modern metal fabrication for workshops that need consistent output, cleaner joints, and controlled cutting paths. Its role continues to expand because industries are shifting toward compact, efficient, and multipurpose equipment that allows skilled workers to tackle several tasks without changing setups. This machine brings welding and cutting into a single practical tool that fits well in daily operations, especially where productivity and accuracy matter.

The handheld format allows operators to move freely around large components or fixed structures instead of repositioning the workpiece. That mobility turns into measurable workflow benefits when the goal is steady throughput and reduced preparation time. Metal fabrication companies, repair shops, and manufacturers use this machine because it supports a wide range of materials and thicknesses, making it reliable across jobs where uniform quality is required.

Its fiber laser source is stable and consistent, which is important for businesses that cannot afford variable performance. A handheld fiber laser welding and cutting machine operates with a beam that keeps its form even over long distances, helping operators maintain a predictable working line. This predictability influences the overall production rhythm of a workshop and helps reduce rework.

Many fabrication teams use this machine to complete welding tasks such as joining stainless steel frames, mild steel enclosures, aluminum parts, and custom components that require a neat seam without extensive grinding afterward. The same machine then switches into cutting mode, allowing workers to make straight lines, curves, or custom shapes directly on the sheet or part. This adaptability turns a single tool into a daily companion for fabricators who want functional performance without switching between several units.

Industries that work with stainless steel typically appreciate how well the handheld fiber laser welding and cutting machine handles joints that must appear neat on both the interior and exterior sides. Food equipment manufacturers, railing installers, and architectural fabricators rely on consistency because their products must look uniform. The machine supports that requirement through heat control and stable energy delivery along the seam.

Workshops that handle aluminum also use this machine for repairing frames, creating lightweight structures, and fabricating custom parts without excessive heat impact. The machine’s controlled thermal effect helps maintain the structural alignment of aluminum components—an important factor for automotive workshops and custom fabrication projects.

A handheld fiber laser welding and cutting machine also has practical value in maintenance and repair operations. Facilities dealing with breakdowns or structural fixes need a tool that can be carried to the location rather than dismantling equipment for transport. The handheld format supports this mobility, allowing technicians to walk into the plant floor, reach tight areas, and complete welds or cuts directly on the asset.

Beyond fabrication and repair, small manufacturing units and independent welders adopt this machine because it brings predictable results even in varied operational conditions. The machine does not require a complex setup, and its power remains stable across long working sessions. This helps teams maintain consistency in batch production or repetitive processing where uniform shapes and joints are important.

For cutting operations, the machine creates precise edges that reduce extra finishing. Many workshops use it to prepare components before bending, assembling, or mounting. The ability to switch from welding to cutting with a single unit streamlines the entire workflow, making it suitable for companies that prefer simplified tools that still deliver professional quality.

Training new operators also becomes more manageable. The handheld fiber laser welding and cutting machine offers steady control and clear operational feedback, allowing beginners to understand the process without feeling overwhelmed. Experienced welders appreciate the responsive beam, which matches their hand movements and lets them complete detailed work with confidence.

In sectors like automotive customization, signage production, furniture fabrication, and precision equipment manufacturing, the machine brings consistency into processes that require both structural strength and visual clarity. It helps maintain production timelines, especially for companies working on tight schedules where repeated repositioning of parts is not feasible.

The handheld fiber laser welding and cutting machine is also valued for how well it integrates into existing workflows. Workshops do not need major layout changes. It can be used alongside traditional processes, giving metalworkers freedom to choose the best method for each project. This hybrid approach lets teams transition into modern tools gradually without interrupting daily operations.

Because the machine supports welding, cutting, and sometimes cleaning preparation, it becomes a complete metal processing system for shops that prefer compact solutions. For repair teams, mobile welding units, and small production facilities, this versatility reduces storage requirements and simplifies equipment management.

Its widespread adoption reflects a clear trend toward more ergonomic and functional metalworking tools. The handheld fiber laser welding and cutting machine stands as a practical response to real-world challenges: limited space, varied material thicknesses, tight deadlines, and the need for accurate work in both manufacturing and repair settings.

Whether used for joining metal frames, preparing sheet components, cutting profiles on-site, or fabricating custom designs, this machine continues to prove itself as a reliable tool for tasks that demand precision and clean workmanship. Its dual-purpose design helps metalworkers create, repair, and refine metal structures with steady performance.

This shift toward multi-use machines is shaping the future of fabrication. Workshops gain the ability to adapt quickly, handle diverse projects, and maintain quality without relying on many separate devices. The handheld fiber laser welding and cutting machine fits naturally into this evolving environment because it brings controlled results in a format that supports both production and on-site service.

As industries continue to explore new fabrication materials, lightweight structures, and detailed designs, tools like this machine become even more central to the workflow. Its combination of mobility, reliable output, and dual welding-cutting function positions it as a long-term companion for metalworkers aiming for stable operations.

Final Thoughts

The handheld fiber laser welding and cutting machine brings practical efficiency to fabrication teams that need dependable performance in both welding and cutting tasks. Its mobility, stability, and wide material compatibility make it suitable for workshops, service crews, and manufacturing units working toward consistent output. As metalworking evolves, this tool stands out as an adaptable solution that supports real-world production needs and everyday operational demands.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness