إعلان مُمول

Embroidery Digitizing Services: Combining Traditional Skill with Modern Innovation

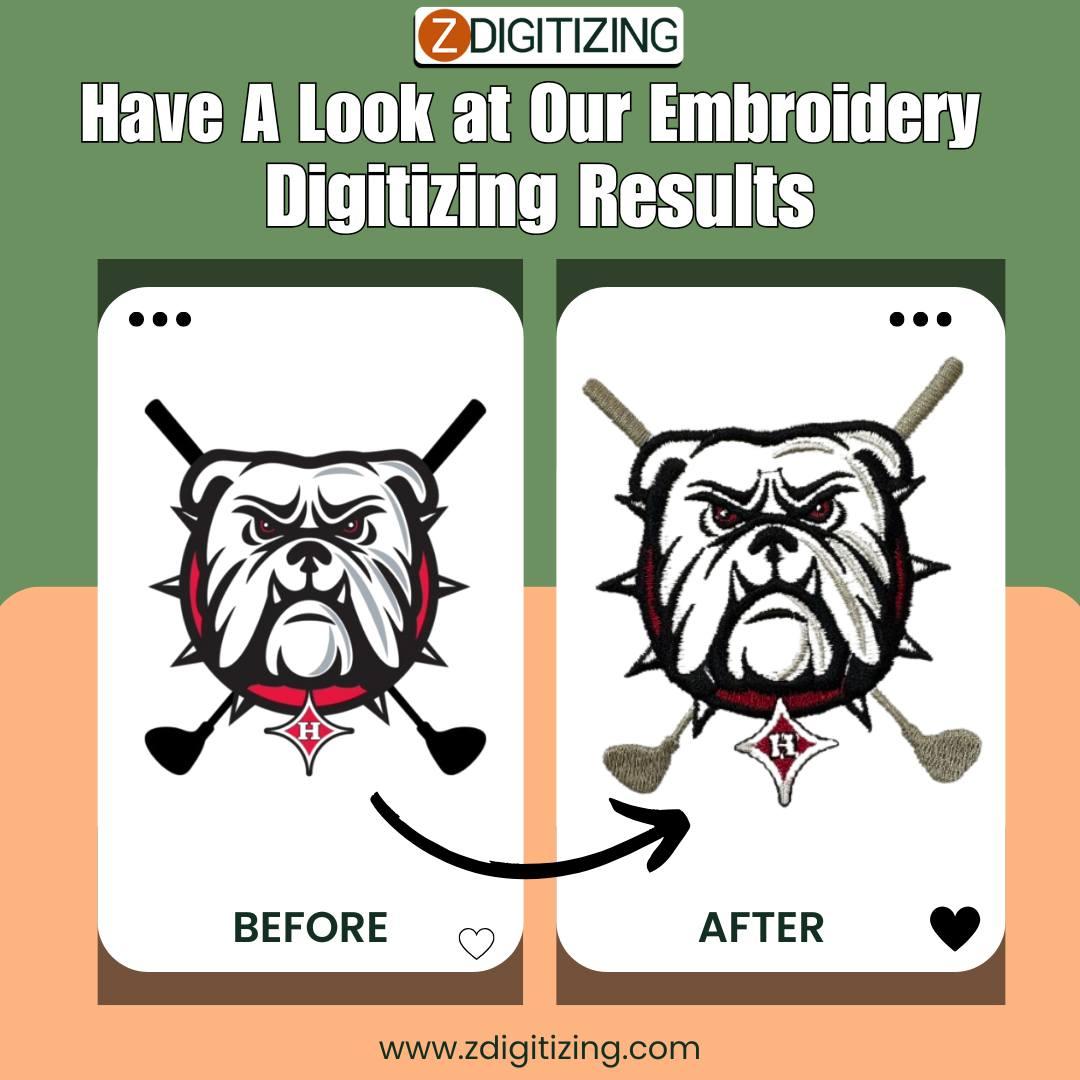

Embroidery has long been associated with artistry, detail, and craftsmanship. From delicate decorative patterns on apparel to company logos on uniforms, embroidery gives a polished and professional finish to any piece of fabric. As the fashion and textile industries evolve, technology has transformed the embroidery process. Embroidery digitizing services have become the key to merging traditional stitching techniques with digital precision.

These services convert artwork or logos into digital embroidery files that machines can read, making it possible to reproduce intricate designs with consistency, speed, and high quality. Whether for branding, fashion, home décor, or promotional materials, embroidery digitizing ensures that every stitch reflects accuracy and professionalism.

Understanding Embroidery Digitizing Services

Embroidery digitizing is the process of translating artwork into a digital format that can be executed by an embroidery machine. This involves creating a stitch map that defines the type, direction, and density of stitches used in the design. Unlike graphic design, digitizing must consider fabric texture, thread thickness, and how stitches will behave when applied to different materials.

A skilled digitizer uses specialized software to plan each stitch carefully. Their role goes beyond technical work; it requires understanding both the artistic intent and the mechanical process to ensure that the final embroidered design matches the original artwork as closely as possible.

Why Embroidery Digitizing Services Matter for Businesses

For companies and designers, embroidery digitizing services are essential to maintaining consistency and efficiency in production. They eliminate manual errors and ensure that every embroidered item meets the same high standard of precision.

Main advantages include:

- Accuracy and Detail: Designs are mapped with exact stitch placement, ensuring clear and defined results.

- Efficiency: Digitized files allow embroidery machines to operate faster, improving productivity and reducing production time.

- Consistency: Each embroidered product looks identical to the original design, which is vital for brand uniformity.

- Cost Savings: Once a design has been digitized, it can be reused multiple times without additional setup costs.

- Adaptability: Designs can easily be scaled or modified to suit different fabrics and garment sizes while maintaining quality.

By integrating digitization into their workflow, businesses can achieve professional results that enhance brand image and production efficiency.

How the Embroidery Digitizing Process Works

The process of embroidery digitizing follows several structured steps, each designed to achieve precision and clarity in the final stitched output.

Preparing the Artwork

The process begins with a high-quality image or logo. The clearer the artwork, the easier it is to convert it into a precise embroidery file.

Selecting Stitch Types

Depending on the design’s structure, digitizers choose appropriate stitch types such as satin, fill, or run stitches to achieve the desired effect.

Setting Stitch Parameters

Direction, density, and sequence of stitches are determined to ensure smooth thread flow and even texture.

Assigning Thread Colors

The digital design is matched with thread colors that best represent the original artwork.

Test Stitching and Adjustments

A sample run is created to verify accuracy, allowing the digitizer to make necessary refinements before production.

Final File Output

Once approved, the design is saved in embroidery machine-compatible formats such as DST, PES, or EXP for seamless use in production.

This step-by-step approach ensures that each design is optimized for both machine performance and visual accuracy.

Advantages of Working with Professional Digitizers

Partnering with experienced embroidery digitizing professionals ensures a higher standard of quality and reliability throughout production.

- Quality Assurance: Expert digitizers understand how stitches interact with different fabrics, preventing issues like thread breaks or distortion.

- Customization Options: Designs can be adapted for specific garments, materials, or thread types.

- Cross-Platform Compatibility: Files are prepared in various formats to work with multiple machine brands and software systems.

- Responsive Service: Many providers offer quick adjustments and ongoing support to ensure client satisfaction.

Professional digitizing services provide the technical foundation for achieving embroidery that looks clean, precise, and consistent on every piece.

Where Embroidery Digitizing Is Used

Digitized embroidery has applications across a wide range of industries, from fashion to corporate branding.

Common uses include:

- Corporate Apparel: Embroidered company logos on uniforms, caps, and jackets.

- Fashion Design: Custom embroidery on garments, denim, and accessories.

- Sportswear: Team logos, names, and numbers on athletic clothing.

- Home Décor: Personalized embroidery on linens, pillow covers, and towels.

- Promotional Items: Branded embroidery on tote bags, hats, and merchandise.

These diverse applications demonstrate how digitizing supports both creativity and commercial branding efforts.

Conclusion

Embroidery digitizing services have revolutionized how embroidery is designed and produced. By converting artwork into digital embroidery files, these services bring together technology and craftsmanship to create precise, consistent, and efficient results.

For designers, manufacturers, and businesses, digitizing offers a dependable solution for producing embroidery that maintains both artistic integrity and professional quality. As innovation advances, embroidery digitizing will continue to refine the balance between creativity and technology, ensuring that every stitch reflects precision and care.