Спонсоры

How High-Progressive Stamping Die Works?

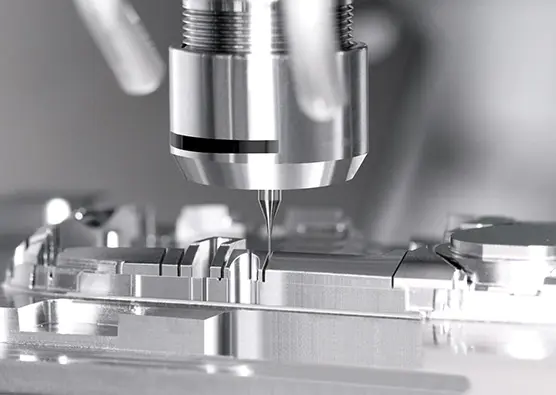

High-Progressive Stamping Die technology represents a significant advancement in metal forming, particularly for high-volume production environments where efficiency and precision matter. This method utilizes a single, sophisticated tool that performs multiple operations—such as punching, bending, and coining—in a coordinated sequence as the metal strip feeds through the press. Each station in the die adds to the part, transforming the raw material into a finished component in one continuous process. The appeal of a High-Progressive Stamping Die lies in this streamlined approach, which can support the manufacturing of complex parts while maintaining consistent output. For businesses looking to scale production, understanding this technology and selecting the right High-Progressive Stamping Die Manufacturer are crucial steps toward achieving reliable results.

So, how does it work in practice? Imagine a coil of metal strip moving through a press. The High-Progressive Stamping Die is mounted in the press, and as the strip advances through each station, different forming operations occur. The initial stations might pierce holes or cut outlines, while subsequent ones form bends or shapes. This progression continues until the final station separates the finished part from the strip. This method reduces the need for multiple handling steps and secondary operations, which can save time and lower production costs. However, the complexity of designing such a tool means that working with an experienced High-Progressive Stamping Die Manufacturer is essential. They have the expertise to plan the sequence of operations, manage material flow, and address potential issues like part distortion or stamping stress.

When evaluating a High-Progressive Stamping Die Manufacturer, it helps to consider their design capabilities and industry experience. A knowledgeable manufacturer will assess your part design, material specifications, and production volume to determine if this method suits your needs. They can suggest adjustments to optimize the design for the stamping process, which may involve simplifying geometries or specifying tolerances that the die can reliably achieve. The goal is to create a High-Progressive Stamping Die that not only produces parts to specification but also supports a stable, efficient manufacturing process. For example, in automotive or electronics applications, where components often require multiple features and high dimensional consistency, a well-made High-Progressive Stamping Die can be a valuable asset.

Building a relationship with your High-Progressive Stamping Die Manufacturer also opens the door to long-term support. They can assist with maintenance, troubleshooting, and even future design updates, helping you adapt to new production requirements. This collaborative approach ensures that your investment in a High-Progressive Stamping Die continues to deliver value, supporting your production line with a tool designed for both performance and durability.

Specification Parameters

| Comprehensive life: | ≥160 million punches |

| Blade die life: | ≥5 million strokes/0.1mm |

| Mold structure: | Three-plate mold base + ball guide |

| Effective cutting edge height: | ≥8mm |

| Blade material: | DJ40 |

| Grooved die form: | Punch grooved die, slow wire finishing, the punch is polished using a special process to remove the oxidation layer |

| Guide parts: | Precision + high hardness |

| Blanking speed during running-in period: | 80-280 punches/minute |

| Blanking speed: | 280-300 punches/minute |

| Concentricity: | ≦0.05mm |

| Protection device: | Equipped with misfeed protection device |

| Punching burr: | ≦0.05mm |

| Riveting force: | 30N |

| Safety device: | Misfeed detection + equal height limit column |

| Product output form: | Conveyor belt Rotor control device Chute control device |

| Plate control device: | Cylinder |

| Mold base material: | Upper and lower mold seats P20, middle unloading seat P20, the second and fourth levels are made on the same set of molds and are interchangeable during production. The shaft hole can be used for three interchangeable pumping plates. |

| Spare parts provided: | 30% of wearing parts |

| Internal plate material: | Cr12MOV |

https://www.motorcoremold.com/product/