U.S.-Japan R&D Collaborations Accelerate Chemical Purity Standards

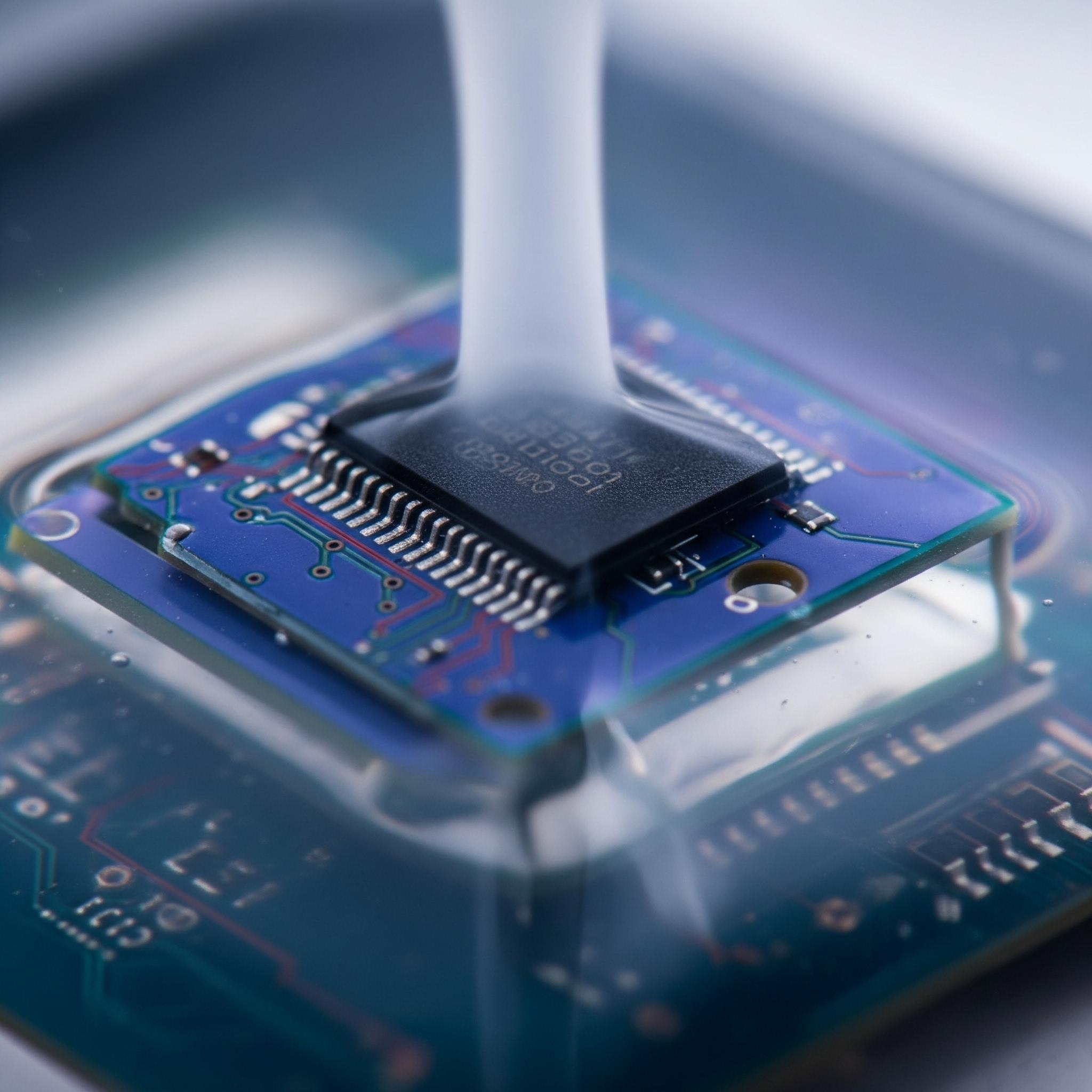

The global Electronic Wet Chemical Market is estimated to grow at a CAGR of 5.0% during the forecast period (2023–2030), driven by surging demand from semiconductor manufacturing, photovoltaics, and advanced electronics. These ultra-high purity chemicals are vital for critical processes such as cleaning, etching, doping, and polishing in wafer fabrication and device assembly. Their role spans multiple phases of electronics production, ensuring performance and reliability in rapidly evolving technologies.

Unlock exclusive insights with our detailed sample report :

https://www.datamintelligence.com/download-sample/electronic-wet-chemical-market

Key Market Drivers

1. Global Semiconductor Expansion

The exponential growth in semiconductor device complexity, from 3D NAND to gate-all-around FETs, has increased reliance on wet process steps and tighter material tolerances.

- Foundries like TSMC, Samsung, and Intel are increasing fab capacity, requiring high-volume procurement of ultrapure acids and solvents.

- The U.S. CHIPS and Science Act and similar initiatives in Japan and the EU are igniting domestic chemical supply chain ***s.

2. Shift Toward Advanced Node Production (Below 5nm)

Advanced nodes require tighter control over particle contamination, metal ions, and trace impurities. Wet chemicals used must conform to ppb- and ppt-level purity standards.

- Etchants and cleans are being customized for EUV lithography compatibility, particularly in Japan and South Korea.

3. Expanding Applications in Displays, Solar, and MEMS

- In OLED/LCD panel fabrication, wet chemicals are vital for glass cleaning, patterning, and photoresist processes.

- In solar cell manufacturing, chemicals like hydrofluoric acid, nitric acid, and ammonium hydroxide are used for wafer texturing and polishing.

- MEMS and sensor production is increasingly relying on batch wet etching to shape microstructures.

4. Environmental and Safety Regulation Pressure

As environmental concerns rise, manufacturers are shifting to:

- Eco-friendly formulations (low-VOC, low-toxicity acids).

- Closed-loop chemical recycling systems.

- Onsite generation of wet chemicals to reduce transport hazards and purity degradation.

Regional Market Insights

United States

The U.S. market is seeing rapid growth due to:

- Expansion of domestic semiconductor fabs (e.g., Intel, Micron, GlobalFoundries).

- Partnership growth between chemical giants (e.g., DuPont, Entegris, BASF) and chipmakers.

- Emphasis on localizing chemical supply chains for strategic autonomy and reliability.

Japan

Japan is a global leader in:

- Producing ultra-high purity electronic chemicals.

- Supplying 70% of global photoresists and a major share of high-purity hydrogen peroxide, sulfuric acid, and ammonia solutions.

- Leading companies like Mitsubishi Gas Chemical, Kanto Chemical, and Sumitomo Seika are investing in capacity upgrades and green chemistries.

The Japanese government has also invested in next-generation material R&D, particularly around quantum computing and sub-2nm lithography, driving innovations in wet chemical purity and process compatibility.

Speak to Our Senior ***yst and Get Customization in the report as per your requirements:

https://www.datamintelligence.com/customize/electronic-wet-chemical-market

Product Landscape

By Product Type:

- Acetic Acid

- Hydrochloric Acid (HCl)

- Hydrofluoric Acid (HF)

- Hydrogen Peroxide (H₂O₂)

- Ammonium Hydroxide (NH₄OH)

- Nitric Acid (HNO₃)

- Sulfuric Acid (H₂SO₄)

- Phosphoric Acid (H₃PO₄)

By Application:

- Semiconductor Fabrication

- Flat Panel Displays (FPD)

- Photovoltaics (PV)

- LED Packaging

- MEMS Devices

Latest Industry Trends

- Custom Chemical Blends for EUV Lithography

EUV tools require specific wet cleaning steps to avoid substrate damage, prompting chemical vendors to launch tailor-made formulations. - Miniaturized Etching and Cleaning for 3D Devices

Wet chemicals optimized for vertical etching and undercut-free cleaning support advanced memory and logic device geometries. - Onsite Chemical Purification Systems Gaining Ground

U.S. fabs are installing point-of-use purification modules to ensure chemical integrity and eliminate long-distance purity degradation. - Japanese Firms Expand Supply for Chinese Foundries Amid Export Rules

Japanese chemical suppliers are increasing indirect exports through third parties due to geopolitical trade controls. - AI-Assisted Process Monitoring in Wet Benches

Wet chemical processing tools now incorporate AI/ML algorithms to optimize chemical concentration, flow rate, and reaction time.

Buy the exclusive full report here:

https://www.datamintelligence.com/buy-now-page?report=electronic-wet-chemical-market

Growth Opportunities

- Next-Gen Node Production (2nm and below): Increasing need for advanced wet chemicals with atomic-level process precision.

- Organic Photovoltaics and Flexible Displays: Niche sectors requiring customized wet processes.

- High-K/Metal Gate Processing: Chemicals tailored for newer dielectric and conductive layers.

- Chemical Reuse Technologies: Developing safe, economical chemical recycling systems.

- Emerging Markets in Southeast Asia: Vietnam, Malaysia, and India are seeing fab activity and growing local demand.

Competitive Landscape

Key players include:

- BASF SE

- Kanto Chemical Co., Inc.

- Avantor Inc.

- Merck KGaA (Sigma-Aldrich)

- Mitsubishi Chemical Corporation

- Fujifilm Holdings Corporation

- Entegris Inc.

- Linde plc

- Honeywell International Inc.

- Dow Chemical Company

Strategic initiatives include:

- Partnerships with chipmakers and foundries for formulation innovation.

- Expansion into ultrapure liquid handling systems.

- Focus on regulatory compliance and green chemistry certifications.

Stay informed with the latest industry insights-start your subscription now:

https://www.datamintelligence.com/reports-subscription

Conclusion

The Electronic Wet Chemical Market is entering a high-growth phase, powered by next-gen chip production, display innovation, and clean energy systems. As fabs become more advanced and the need for high-purity, eco-safe process chemicals grows, global leaders are racing to innovate and expand capacity.

The U.S. and Japan remain at the forefront of this technological evolution, with coordinated industry-government action to secure supply chains, ensure chemical purity, and enhance competitive advantage. The future of electronics—from quantum processors to solar panels—depends on the precision chemistry enabled by wet chemicals.

DataM Intelligence is a premier provider of market research and consulting services, offering a full spectrum of business intelligence solutions—from foundational research to strategic consulting. We utilize proprietary trends, insights, and developments to equip our clients with fast, informed, and effective decision-making tools.

Our research repository comprises more than 6,300 detailed reports covering over 40 industries, serving the evolving research demands of 200+ companies in 50+ countries. Whether through syndicated studies or customized research, our robust methodologies ensure precise, actionable intelligence tailored to your business landscape.

Contact US:

Company Name: DataM Intelligence

Contact Person: Sai Kiran

Email: sai.k@datamintelligence.com

Phone: +1 877 441 4866

Website: https://www.datamintelligence.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness