High-Quality Orthopedic Surgical Instruments for Precision Surgery

Summary

This guide talks about orthopedic surgical instruments and why they matter so much in bone surgery. We'll look at different types of instruments doctors use, explain why good quality tools make surgery safer, share some new technology that's changing how these tools work, help you pick the right instruments for different surgeries, and show you how to take care of these expensive tools so they last longer.

What Types of Orthopedic Surgical Instruments Do We Actually Use?

Over the years, I've worked with hundreds of different instruments, but they usually fall into a few main groups that every orthopedic team needs to know about.

The cutting tools are probably what most people think of first. We use bone saws, chisels, and osteotomes to cut through bone tissue. I'll never forget the first time I held a high-quality bone saw - it felt completely different from cheaper versions I'd used before. The weight was perfect, the blade stayed sharp throughout the entire procedure, and it cut cleanly without causing unnecessary damage to surrounding tissue.

The drilling equipment is another essential category. We use these orthopedic surgical instruments to create precise holes for screws and implants. I've seen surgeries delayed because a cheap drill bit broke mid-procedure. That's why we always invest in quality drilling tools - they're more reliable and create cleaner holes.

Why Quality Really Matters in the Operating Room

Here's something I learned the hard way early in my career: cheap instruments cost more in the long run. I was working at a smaller hospital that had budget constraints, and we were using some lower-grade tools to save money.

During one hip replacement surgery, our bone saw started getting dull halfway through the procedure. Instead of making clean cuts, it was essentially crushing the bone, creating rough edges that made it difficult to fit the implant orthopedic surgical instruments properly. The surgery took an extra hour, the patient had more bleeding than expected, and we had to use additional anesthesia. That one "cost-saving" instrument ended up costing much more in OR time and potentially affected the patient's recovery.

Quality orthopedic surgical instruments maintain their sharpness and precision throughout long procedures. When you're working on someone's hip or knee - joints they'll depend on for the rest of their life - you can't afford to have tools that fail when you need them most.

I've also noticed that high-quality instruments are easier on the surgeon's hands. During a long spinal fusion surgery, using well-***gned, ergonomic instruments means less hand fatigue and better control. This isn't just about comfort - it's about maintaining precision when every movement matters.

The Science Behind Modern Instrument Manufacturing

The materials used in today's orthopedic surgical instruments are pretty incredible when you really look into them. Most of our best tools are made from specialized stainless steel alloys that have been engineered specifically for medical use.

I had a chance to visit an instrument manufacturing facility a few years ago, and it was eye-opening. The steel they use goes through multiple heat treatments and quality checks. Each instrument is tested to make sure it can handle the stress of cutting through bone repeatedly without losing its edge or breaking.

New Technology That's Changing Everything

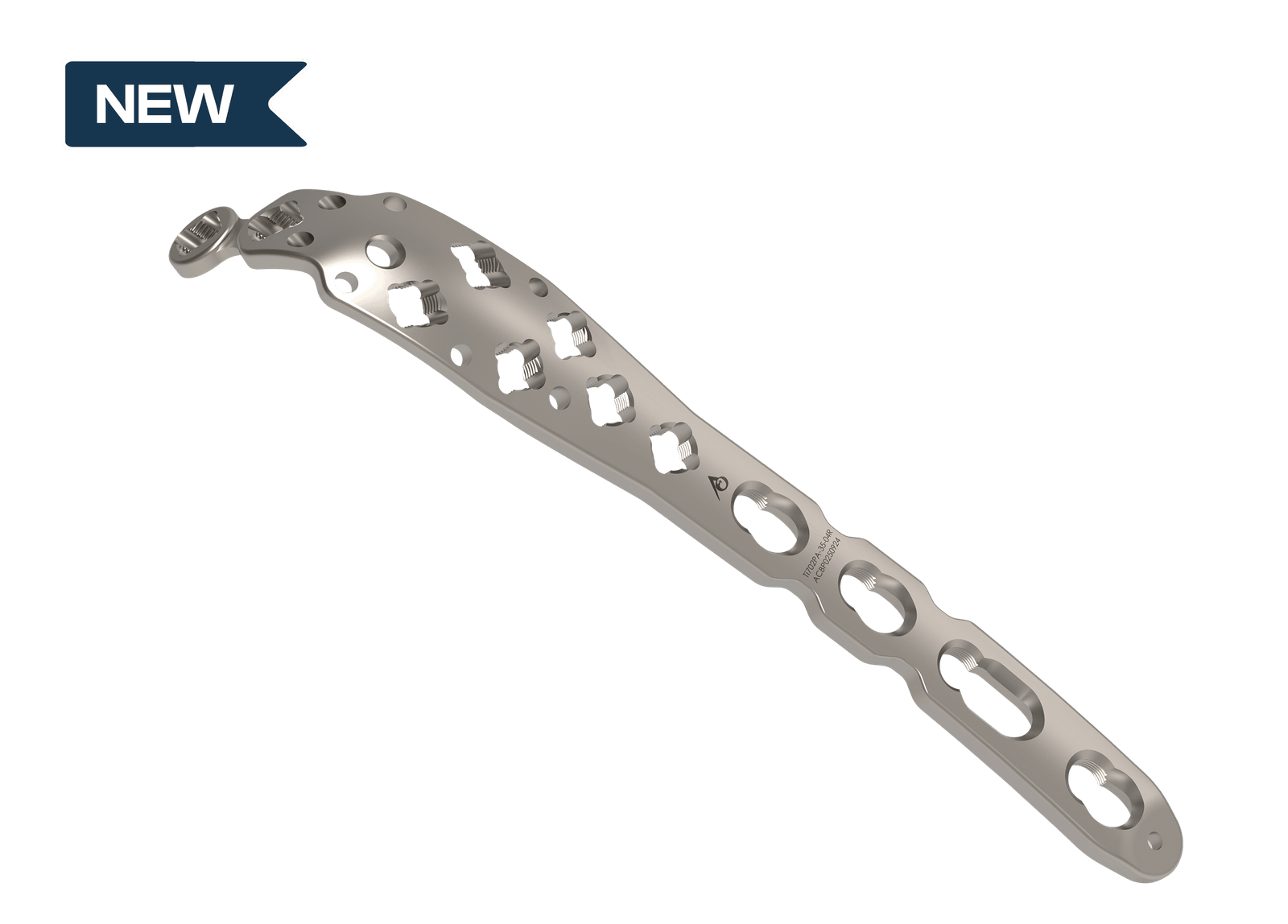

The advances I've seen in orthopedic surgical instruments over the past few years have been amazing. We're starting to use instruments that are ***gned specifically for individual patients using 3D printing technology.

Just last month, we had a patient with a complex pelvic fracture. The engineering team created custom cutting guides and reduction tools based on the patient's CT scan. These patient-specific instruments allowed us to perform the surgery with incredible precision - something that would have been much more difficult with standard tools.

I'm also excited about the "smart" instruments that are starting to appear. These tools have sensors that can tell the surgeon how much force they're applying or help guide them to the exact right position. It's like having GPS for surgery.

Some of the newer powered instruments are incredibly sophisticated too. The saws and drills we use now can automatically adjust their speed and power based on the density of the bone they're cutting through. This helps prevent overheating and reduces the risk of tissue damage.

How to Choose the Right Instruments for Different Surgeries

After years of working with different surgical teams, I've learned that choosing the right orthopedic surgical instruments for each procedure is both an art and a science.

For joint replacement surgeries, we need instruments that can make very precise cuts and measurements. The cutting guides we use for knee replacements, for example, need to be accurate to within millimeters. If the cuts aren't perfect, the artificial joint won't fit properly, and the patient might have pain or limited mobility.

Trauma surgery is completely different. When we're dealing with fractures from car accidents or falls, we need instruments that can handle unpredictable situations. We might need to work with bone that's shattered into many pieces, or deal with hardware that's already in place from previous surgeries. Our instrument sets for trauma cases include a wider variety of clamps, plates, and screws to handle whatever we might encounter.

Taking Care of These Expensive Tools

One thing I always tell new staff is that these instruments are ***s that need proper care. A good set of orthopedic surgical instruments can cost tens of thousands of dollars, so we need to make them last.

Cleaning is the first and most important step. Every instrument needs to be thoroughly cleaned immediately after use to remove all blood and tissue. We use enzymatic cleaners that break down proteins and make sure nothing is left behind that could interfere with sterilization.

The sterilization process itself needs to be carefully controlled. Different instruments might need different sterilization methods, and using the wrong process can damage the tools. I've seen expensive instruments ruined because someone put them through the wrong sterilization cycle.

How Do You Know When Instruments Need Attention?

After working with these tools for years, I've developed a good sense of when something isn't right. Visual inspection is always the first step - any chips, cracks, or unusual wear patterns are red flags.

For cutting instruments, if they're requiring more force than usual or leaving rough cuts, they probably need sharpening or replacement. I can usually tell just by the feel when a saw or drill bit isn't performing like it should.

Frequently Asked Questions

What are the most important things to look for when buying orthopedic surgical instruments?

From my experience, the most important factors are the quality of materials, the reputation of the manufacturer, and the availability of service and support. I always recommend buying from established companies that specialize in orthopedic instruments and have a track record of standing behind their products. Make sure the instruments feel comfortable in your hands and meet all the regulatory requirements for your area. Don't forget to consider warranty coverage and repair services - even the best instruments sometimes need maintenance.

How often should we replace our orthopedic surgical instruments?

This really depends on how much you use them and how well you take care of them. In a busy trauma center, cutting instruments might need replacement or refurbishment every few years. In a lower-volume practice with excellent maintenance, high-quality instruments can last a decade or more. I recommend establishing a systematic evaluation process rather than just replacing things on a schedule. Look at performance, safety, and cost-effectiveness to make replacement decisions.

What kind of training should our staff have for handling these instruments?

Everyone who handles orthopedic surgical instruments should understand proper cleaning, sterilization, and storage procedures. They need to know how to inspect instruments for damage and when to remove questionable tools from service. I also think it's important for staff to understand why these instruments are so expensive and how proper care protects that ***. Regular training updates help ensure everyone stays current with best practices, especially as new instruments and procedures are introduced.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness