Спонсоры

Japan's Metal Injection Molding Market Surges with EV Growth

The global metal injection molding (MIM) market is set for remarkable growth, with its value projected to surpass USD 6.7 billion by 2031, growing at a CAGR of 7.9% during the forecast period (2024–2031). As industrial trends shift toward miniaturization, cost-efficiency, and material performance, MIM has become a pivotal technology enabling the mass production of high-strength, complex metal parts with exceptional precision.

Unlock exclusive insights with our detailed sample report :

https://www.datamintelligence.com/download-sample/metal-injection-molding-market

Market Overview

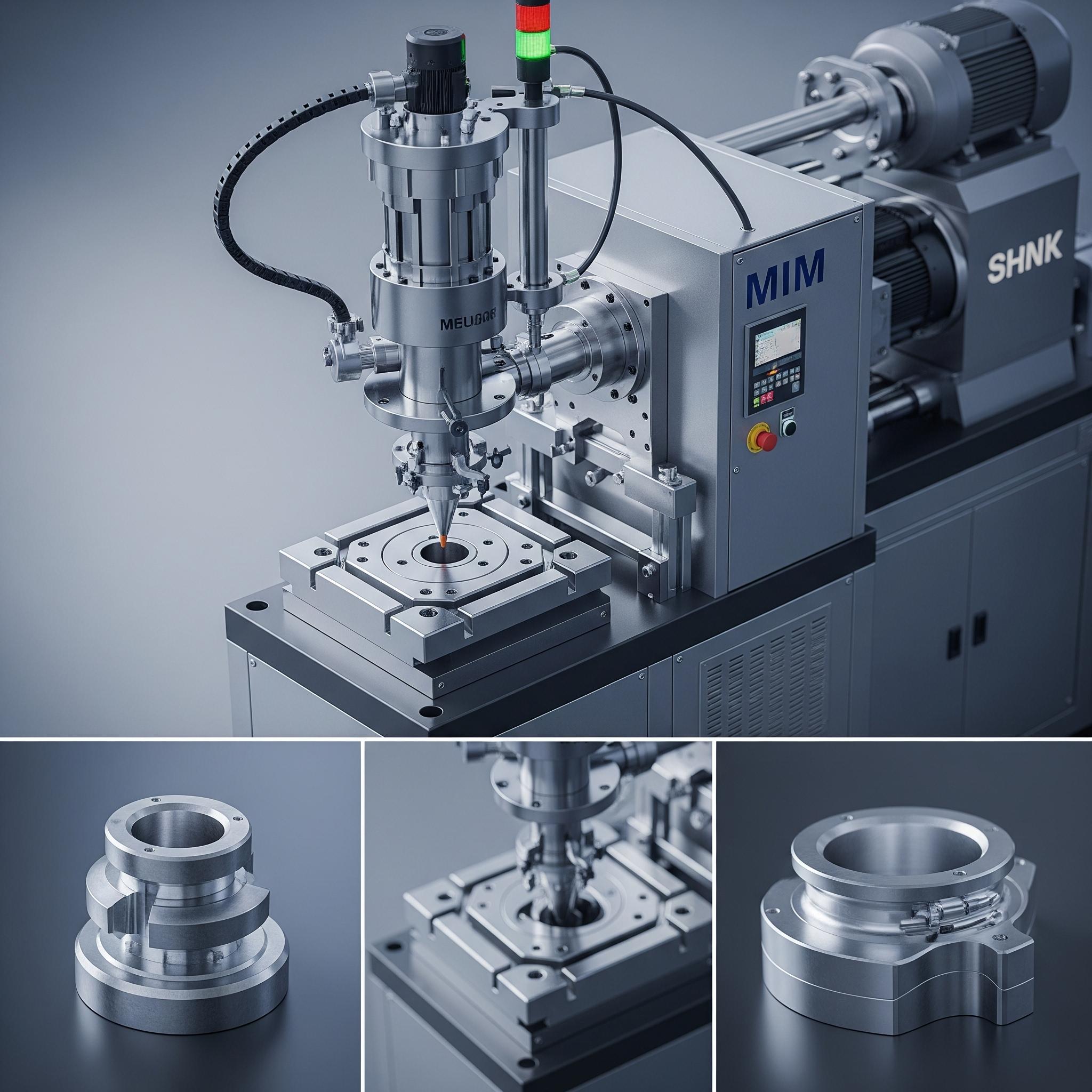

Metal injection molding is a manufacturing process that blends metal powders with a binder material to form a feedstock suitable for injection molding. This method is particularly advantageous for producing intricate, small-to-medium-sized metal components in high volumes with minimal material waste.

The increasing demand for high-performance, precision-engineered components in industries such as automotive, aerospace, medical devices, electronics, and defense is fueling the widespread adoption of MIM across the globe.

Key Market Drivers

- Rising Adoption in Automotive and Aerospace Sectors

- The automotive industry is one of the largest adopters of MIM due to the demand for lightweight, durable components. MIM enables the production of turbochargers, sensors, and fuel system parts with consistent quality.

- In aerospace, weight reduction without compromising strength is critical. MIM facilitates the creation of complex shapes in single processes, reducing assembly time and material costs.

- Miniaturization of Electronics

- The consumer electronics sector is witnessing a boom in demand for smaller, lighter, and more durable components. MIM allows manufacturers to produce miniature connectors, structural parts, and enclosures with high tolerances, especially in smartphones, wearable devices, and laptops.

- Medical Industry Expansion

- MIM is transforming medical device manufacturing by enabling high-volume production of surgical instruments, orthodontic brackets, and implantable components that require biocompatibility and corrosion resistance.

- Sustainability and Eco-Efficiency

- Unlike traditional machining, MIM minimizes material waste. Its eco-friendly nature aligns well with the global shift toward sustainable manufacturing. The near-net-shape capability of MIM drastically reduces post-processing needs.

- Technological Advancements and Material Innovations

- Development of advanced materials, including stainless steel, titanium, and cobalt-chromium alloys, is expanding MIM applications. Moreover, improvements in feedstock technology and sintering techniques have enhanced mechanical properties and surface finish.

Stay informed with the latest industry insights-start your subscription now:

https://www.datamintelligence.com/reports-subscription

Latest Trends and Industry News: U.S. and Japan

United States:

The U.S. MIM market is experiencing rapid expansion, with revenues expected to exceed USD 2 billion by 2030. This growth is driven by:

- High defense spending and aerospace component demand.

- The med-tech boom, especially in orthopedics and dental implants.

- OEMs increasingly opting for MIM for its cost-effective scalability and quality assurance in small, complex components.

Major U.S.-based players, including Phillips-Medisize and OptiMIM, are investing in R&D and expanding their manufacturing capacities to meet growing domestic and export demand.

Japan:

Japan is emerging as a key MIM innovation hub, especially in:

- Electric vehicle (EV) manufacturing, where lightweight, high-strength components are critical.

- Miniature electronics and precision sensors, essential for Japan’s dominant consumer electronics and robotics sectors.

Recent industry developments in Japan include the integration of AI-driven process optimization in MIM production lines to improve defect detection and enhance material flow simulations.

Regional ***ysis

- Asia-Pacific remains the largest regional market, accounting for over 35% of global revenue. Countries like China, Japan, South Korea, and India are leading MIM adoption in electronics and automotive sectors.

- North America follows, driven by strong demand in medical, aerospace, and defense industries. The region is projected to grow at a CAGR of over 8.2%.

- Europe maintains a significant presence in automotive MIM components, with Germany, France, and the UK showing strong industrial demand.

Segmentation ***ysis

By Material:

- Stainless Steel

- Titanium Alloys

- Copper

- Nickel

- Others

By Industry:

- Automotive

- Medical & Dental

- Consumer Electronics

- Aerospace & Defense

- Industrial Machinery

By Region:

- North America (U.S., Canada)

- Europe (Germany, UK, France, Italy)

- Asia-Pacific (China, Japan, South Korea, India)

- Latin America

- Middle East & Africa

Key Players in the Metal Injection Molding Market

- Indo-MIM Pvt. Ltd.

- Phillips-Medisize (Molex LLC)

- Dynacast International Inc.

- CMG Technologies

- Plansee Group

- Advanced Materials Technologies Pte Ltd

- Smith Metal Products

- NetShape Technologies Inc.

- MIM International

These players are investing in new facilities, automation technologies, and cross-sector collaborations to expand their portfolios and stay ahead in a highly competitive landscape.

Growth Opportunities

- High-performance metals like titanium and specialty alloys for aerospace and medical markets.

- Binder system innovations to improve flowability and reduce environmental impact.

- Additive manufacturing (AM) integration: Combining MIM with metal 3D printing offers flexible ***gn and short lead times.

- Customized MIM solutions for micro-components and hybrid material parts.

Buy the exclusive full report here:

https://www.datamintelligence.com/buy-now-page?report=metal-injection-molding-market

Conclusion

The global metal injection molding market stands at the crossroads of manufacturing innovation and economic expansion. As industries demand greater efficiency, precision, and sustainability, MIM emerges as a powerful solution—redefining how the world builds everything from cars and electronics to implants and defense systems.

With notable growth in the U.S. and Japan, backed by robust R&D and automation, MIM is no longer a niche but a necessity. The next decade will likely witness the integration of smart technologies, green practices, and new materials, reinforcing MIM’s role in future-ready manufacturing.