Unleash Calm and Joy with Coloring Pages Of A Dog

Afternoons turn noisy, screens flare, and patience thins; I needed a small fix that worked fast. I tried Coloring Pages Of A Dog—easy to print, easy to start—and the mood at home changed. It became our go-to DIY activity for mindful coloring, kids entertainment, and low-cost family fun. I curate and share the set at ColoringPagesJourney, and my reference hub sits here:

https://coloringpagesjourney.com/dog-coloring-pages

Why Coloring Pages Of A Dog Work for Families

Familiar pups, friendly faces, and everyday scenes lower the barrier to begin, so everyone joins in without a pep talk. We color, chat, and calm down together.

A quick routine that brings people together

We lay sheets on the kitchen table, grab pencils, and set a fifteen-minute timer. Print, color, chat, repeat—it keeps boredom at bay and becomes a kitchen-table classic. Parents write, “One page before dinner turned into our nightly reset.”

What educators and experts say

Anna Lewis, PhD (Education, UCL), notes that brief coloring “supports calm focus and fine-motor control,” which helps kids transition between tasks. Prof. Mateo Ruiz, child psychologist in Madrid with 12+ years of practice, adds that animal themes “invite empathy and storytelling,” so the activity feels like play, not homework.

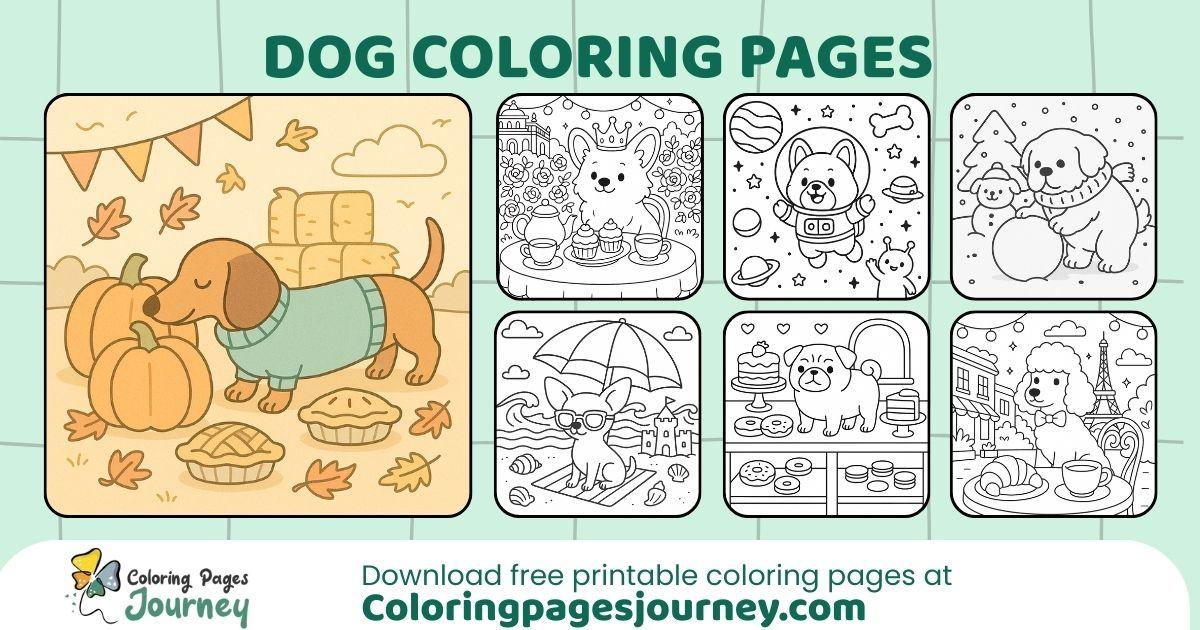

What You Get in My Collection

I built a flexible set—bold outlines for little hands, richer details for grown-ups, plus seasonal scenes for weekends and holidays. I post small updates and polls at

https://www.facebook.com/dogcoloringpages/ so families can vote on what comes next. In my metadata I keep one broad anchor term—Dog Coloring Pages—then use natural variants throughout.

Formats, printing tips, and quick wins

Home-printer-friendly PDFs and PNGs in A4 or Letter work fine; normal paper for crayons, thicker stock for markers. I include free printable coloring pages for busy weekdays and simple coloring pages for kids for classrooms and playdates. It’s quick and easy: pick a page, print on demand, and you’re rolling.

How to Start and Keep the Habit

Short bursts****. A small ritual beats a once-a-month marathon, and it’s easier to repeat tomorrow.

Rituals that stick

Choose a time—after school or before bed. Keep a pencil caddy ready. Write names and dates; make a fridge gallery; swap pages with neighbors. Small touches turn sheets into keepsakes.

Share and learn as a community

Real voices keep me honest:

“Rainy-day savior,” says Kelsey W., Boston. “Ten minutes and the mood changed.”

“Perfect for grandparents,” notes Ahmed S., Manchester. “We color side by side and talk about our old family dog.”

“Quiet after work,” writes Hana R., Tokyo. “Mindful coloring feels like a reset.”

People Also Ask

Q: What age range is best?

A: Preschoolers like bold shapes; older kids prefer medium detail; adults often choose realistic coats and scenic outlines.

Q: How many pages should I print?

A: Two or three at a time—keep it fresh, avoid overwhelm, rotate themes weekly.

Q: Can this help transitions at home?

A: Yes. Short, predictable breaks act as buffers between activities, a tip many educators with 10+ years of experience recommend.

Q: Any budget tips?

A: Print two-up per sheet, reuse scraps, and bind finished pages into a homemade book—simple, low-cost family fun.

For 2025 I’m refreshing sets steadily, adding light breed notes, and keeping files small for phones and school portals. I share a weekly audio note about scene ideas here:

https://soundcloud.com/coloringpagesjourney/free-dog-coloring-pages-for-calm-focus-and-everyday-joy

If you want a ready stack, look for Dog Coloring Pages Printable at the close of each pack; it pairs well with tea and fifteen quiet minutes. I’ll keep building as a maker and a parent, pointing folks to ColoringPagesJourney, because that’s the home of this collection and where I post updates. Thanks for visiting—and may Coloring Pages Of A Dog help your home settle, smile, and breathe.

Unleash Calm and Joy with Coloring Pages Of A Dog

Afternoons turn noisy, screens flare, and patience thins; I needed a small fix that worked fast. I tried Coloring Pages Of A Dog—easy to print, easy to start—and the mood at home changed. It became our go-to DIY activity for mindful coloring, kids entertainment, and low-cost family fun. I curate and share the set at ColoringPagesJourney, and my reference hub sits here: https://coloringpagesjourney.com/dog-coloring-pages

Why Coloring Pages Of A Dog Work for Families

Familiar pups, friendly faces, and everyday scenes lower the barrier to begin, so everyone joins in without a pep talk. We color, chat, and calm down together.

A quick routine that brings people together

We lay sheets on the kitchen table, grab pencils, and set a fifteen-minute timer. Print, color, chat, repeat—it keeps boredom at bay and becomes a kitchen-table classic. Parents write, “One page before dinner turned into our nightly reset.”

What educators and experts say

Anna Lewis, PhD (Education, UCL), notes that brief coloring “supports calm focus and fine-motor control,” which helps kids transition between tasks. Prof. Mateo Ruiz, child psychologist in Madrid with 12+ years of practice, adds that animal themes “invite empathy and storytelling,” so the activity feels like play, not homework.

What You Get in My Collection

I built a flexible set—bold outlines for little hands, richer details for grown-ups, plus seasonal scenes for weekends and holidays. I post small updates and polls at https://www.facebook.com/dogcoloringpages/ so families can vote on what comes next. In my metadata I keep one broad anchor term—Dog Coloring Pages—then use natural variants throughout.

Formats, printing tips, and quick wins

Home-printer-friendly PDFs and PNGs in A4 or Letter work fine; normal paper for crayons, thicker stock for markers. I include free printable coloring pages for busy weekdays and simple coloring pages for kids for classrooms and playdates. It’s quick and easy: pick a page, print on demand, and you’re rolling.

How to Start and Keep the Habit

Short bursts win. A small ritual beats a once-a-month marathon, and it’s easier to repeat tomorrow.

Rituals that stick

Choose a time—after school or before bed. Keep a pencil caddy ready. Write names and dates; make a fridge gallery; swap pages with neighbors. Small touches turn sheets into keepsakes.

Share and learn as a community

Real voices keep me honest:

“Rainy-day savior,” says Kelsey W., Boston. “Ten minutes and the mood changed.”

“Perfect for grandparents,” notes Ahmed S., Manchester. “We color side by side and talk about our old family dog.”

“Quiet after work,” writes Hana R., Tokyo. “Mindful coloring feels like a reset.”

People Also Ask

Q: What age range is best?

A: Preschoolers like bold shapes; older kids prefer medium detail; adults often choose realistic coats and scenic outlines.

Q: How many pages should I print?

A: Two or three at a time—keep it fresh, avoid overwhelm, rotate themes weekly.

Q: Can this help transitions at home?

A: Yes. Short, predictable breaks act as buffers between activities, a tip many educators with 10+ years of experience recommend.

Q: Any budget tips?

A: Print two-up per sheet, reuse scraps, and bind finished pages into a homemade book—simple, low-cost family fun.

For 2025 I’m refreshing sets steadily, adding light breed notes, and keeping files small for phones and school portals. I share a weekly audio note about scene ideas here: https://soundcloud.com/coloringpagesjourney/free-dog-coloring-pages-for-calm-focus-and-everyday-joy

If you want a ready stack, look for Dog Coloring Pages Printable at the close of each pack; it pairs well with tea and fifteen quiet minutes. I’ll keep building as a maker and a parent, pointing folks to ColoringPagesJourney, because that’s the home of this collection and where I post updates. Thanks for visiting—and may Coloring Pages Of A Dog help your home settle, smile, and breathe.