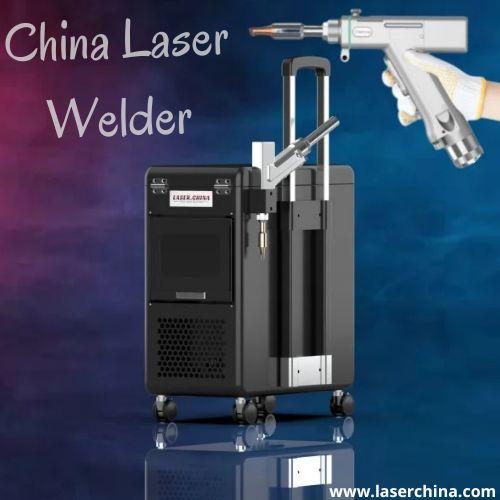

China Laser Welder Shaping Global Manufacturing with Precision, Power, and Modern Technology

The China Laser Welder has become a cornerstone of modern manufacturing, redefining how industries approach metal fabrication, automotive production, and precision engineering. As China continues to lead in the development and export of laser-based machinery, its laser welders are gaining international recognition for delivering accuracy, speed, and reliability that meet industrial demands on a global scale.

Over the past decade, China has shifted from being a low-cost equipment producer to a competitive technology innovator. Today, the China Laser Welder represents this transformation — a powerful combination of engineering expertise, advanced fiber laser systems, and smart control technology. These welders have evolved into essential tools for small workshops, large-scale factories, and high-end manufacturing sectors seeking efficient, consistent, and clean welding results.

The Technological Foundation Behind China Laser Welders

Laser welding works by focusing a high-energy laser beam onto the workpiece, melting the material edges and forming a strong joint upon cooling. In the case of the China Laser Welder, this process is optimized through precision optics, advanced control software, and modern cooling systems. The technology integrates fiber laser sources that produce a concentrated and stable beam, suitable for joining metals like stainless steel, aluminum, carbon steel, copper, and titanium.

What sets Chinese manufacturers apart is their continuous improvement of system integration. Many of the latest machines feature automated control panels, adjustable welding parameters, and ergonomic hand-held or robotic configurations. This adaptability allows users to perform complex welding tasks, from micro-welding in electronics to deep penetration welds in automotive or shipbuilding applications.

Industrial Applications Expanding Worldwide

The adoption of China Laser Welders extends across multiple sectors. In the automotive industry, laser welding ensures durable seams on body panels, exhaust systems, and battery housings for electric vehicles. In electronics, precision welders are used to assemble miniature components without damaging nearby circuits. The medical sector relies on them for producing stainless steel instruments and implantable devices that require seamless joints and flawless finishes.

Manufacturers of household appliances, metal furniture, aerospace components, and energy equipment also rely on Chinese laser welders to enhance productivity and maintain consistent quality. As sustainability and energy efficiency become key goals, laser welding’s minimal material waste and low maintenance requirements align perfectly with modern production strategies.

Evolution of China’s Laser Welding Industry

China’s laser industry began its rapid rise in the early 2000s, driven by government investment and collaboration with global research institutions. Over time, the China Laser Welder became a symbol of this growth, combining cost-effective design with technological refinement. Companies based in industrial hubs like Shenzhen, Wuhan, and Suzhou now supply machines to more than 80 countries, establishing a solid reputation in both quality and performance.

This evolution is supported by domestic innovation in fiber laser sources — the core component of every laser welder. With increasing investment in research and optical manufacturing, China has achieved near self-sufficiency in producing high-power laser modules and precision optics. This independence not only reduces production costs but also accelerates product development cycles, enabling continuous improvement in welding precision and output power.

Integration with Smart Manufacturing

The modern China Laser Welder is not just a standalone device; it is part of a connected, data-driven production ecosystem. Integration with computer-aided design (CAD), automation software, and robotic arms allows real-time monitoring and adaptive control. These capabilities enhance process consistency while reducing operator dependency.

Factories are now adopting smart welding stations where the welder automatically adjusts to material thickness, angle, and reflective properties. Through digital interfaces, users can record welding parameters, optimize settings, and store operational data for quality control. This smart transformation is positioning Chinese welding systems as a key enabler in Industry 4.0 manufacturing environments.

The Global Shift Toward Chinese Welding Solutions

A growing number of companies worldwide are investing in China Laser Welders due to their adaptability and cost performance. Small and medium enterprises (SMEs) in Europe and North America are turning to Chinese suppliers to access industrial-grade welders without excessive financial barriers. The availability of after-sales support, online diagnostics, and multilingual software further encourages international adoption.

In developing regions, these machines help local manufacturers modernize their workshops, reduce manual welding labor, and achieve consistent quality in export production. The accessibility of replacement parts and technical assistance has also helped build long-term trust between Chinese suppliers and global buyers.

Quality and Precision in Manufacturing

Precision remains a defining characteristic of the China Laser Welder. The laser beam’s narrow focus allows for controlled heat input, producing clean weld seams without distortion. This precision is essential in industries where tolerance levels are minimal and visual aesthetics matter. For instance, high-end kitchen appliances and jewelry manufacturers use laser welders to achieve flawless finishes that cannot be obtained through traditional arc welding methods.

Moreover, advancements in power control and beam delivery systems have made it possible to weld dissimilar metals — a critical requirement in battery production and electronic device assembly. These capabilities illustrate how China’s engineering progress directly supports innovation in downstream industries.

Environmental and Operational Efficiency

Laser welding is inherently more energy-efficient than conventional welding methods. With lower heat generation and minimal material waste, the China Laser Welder supports sustainable production objectives. The process eliminates the need for filler materials or extensive surface finishing, reducing both material consumption and processing time.

This operational efficiency is especially beneficial for large-scale manufacturers aiming to optimize output without increasing their environmental footprint. Reduced fume generation and minimal distortion contribute to cleaner workshops and safer working conditions — essential components of modern industrial management.

Continuous Innovation and Global Collaboration

Chinese laser equipment manufacturers are collaborating with universities, research centers, and international technology firms to further enhance laser performance and automation capabilities. Innovations such as dual-beam welding, adaptive cooling, and AI-assisted process optimization are being integrated into next-generation China Laser Welders.

Through global exhibitions and partnerships, Chinese brands are expanding their presence in regions like the Middle East, South America, and Eastern Europe. These collaborations foster technical exchange and ensure that products align with international safety and performance standards, further strengthening China’s reputation in the laser technology field.

Market Growth and Future Prospects

The global demand for laser welding machines continues to rise, with China maintaining a leading share of exports. As industries shift toward electric vehicles, renewable energy systems, and lightweight materials, the precision and versatility of China Laser Welders will play an even more critical role.

Ongoing investments in automation and smart factory solutions indicate that Chinese manufacturers are prepared to meet complex industrial requirements. The combination of performance, affordability, and scalability makes these welders an attractive choice for businesses planning to upgrade from traditional welding systems.

Final Thoughts

The China Laser Welder stands as a testament to China’s engineering advancement and global industrial influence. It blends precision, adaptability, and technological maturity into a solution that drives productivity and quality across sectors. As the world embraces smarter, cleaner, and faster production processes, China’s role in providing reliable laser welding systems will only continue to expand.

From intricate micro-welding tasks to high-strength industrial assemblies, the China Laser Welder embodies the direction of modern manufacturing — precise, efficient, and future-ready.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness