Demystifying CNC Machining: Precision Manufacturing for Modern Industries

In today's competitive manufacturing environment, product teams often face the pressure of balancing cost, precision, and speed. Imagine a startup developing high-performance drone components or a procurement team managing thousands of custom metal parts for a medical device — these challenges demand a solution that ensures accuracy and repeatability. Understanding what is cnc machining becomes crucial when quality, efficiency, and scalability are non-negotiable in production planning.

The Critical Role of CNC Machining in Precision Manufacturing

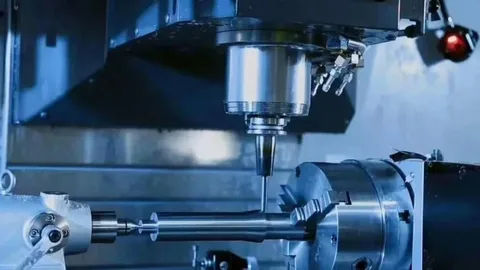

CNC (Computer Numerical Control) machining has become the backbone of modern industrial production. It enables the creation of highly complex and dimensionally accurate parts from metals, plastics, and composites — vital for industries like aerospace, medical, defense, and electronics.

What makes CNC machining so indispensable is its ability to execute intricate designs with minimal human intervention. When tolerances as tight as ±0.001 inches are required, manual machining simply cannot compete. Automated CNC systems interpret digital CAD models and translate them into precise tool movements, resulting in consistent quality across low- and high-volume production runs. For manufacturers, this means fewer errors, reduced waste, and predictable lead times.

Core Concepts Every Engineer and OEM Should Understand

The Mechanics Behind CNC Machining

CNC machining is a subtractive process where material is removed from a workpiece to achieve the final shape. Unlike manual machining, CNC operations are automated through G-code instructions that control spindle speed, feed rate, cutting path, and more. This enables tight dimensional control and fast changeovers, especially when dealing with complex geometries or multi-axis configurations.

CNC machines can handle various processes, including milling, turning, drilling, grinding, and EDM (electrical discharge machining). Each method is suited to different part geometries and materials, offering flexibility across industries.

Material Considerations: From Aluminum to Exotic Alloys

The success of any CNC machining project starts with the right material choice. For example, aerospace parts often use titanium or Inconel due to their strength-to-weight ratios and heat resistance. Meanwhile, automotive and electronics sectors might prefer aluminum for its machinability and thermal conductivity.

Each material responds differently to cutting forces, so selecting the appropriate tooling and machining parameters is essential. MYT Machining’s material expertise ensures optimal outcomes regardless of complexity — from brass bushings to hardened stainless steel enclosures.

Tolerances, Surface Finishes, and Compliance Standards

CNC machining is not just about cutting parts — it's about meeting exact performance specifications. Tolerances define how much deviation is acceptable in part dimensions, often down to microns. In sectors like medical or semiconductor manufacturing, even minor deviations can lead to critical failures.

Surface finish also plays a vital role. Some parts require mirror finishes for sealing or friction reduction, while others need rougher textures for better adhesion or bonding. MYT Machining’s precision tools and inspection protocols ensure every part meets your project’s engineering and regulatory requirements.

In-House vs Outsourced CNC Machining: What’s More Efficient?

While in-house CNC machining may offer control, it demands significant investment in equipment, software, training, and maintenance. It also diverts internal resources from core product development.

Outsourcing to a specialized CNC machining partner provides access to cutting-edge technology, broader material capabilities, and scalable production without infrastructure overhead. For startups or OEMs scaling up, partnering with experts like MYT Machining is not just cost-effective — it’s a competitive advantage.

What Makes a CNC Machining Partner Truly Reliable?

Selecting the right machining partner is a strategic decision. Engineering teams and procurement managers should prioritize vendors who are ISO-certified, experienced with complex assemblies, and capable of high-mix, low-volume production. The ability to handle tight timelines, work with specialized materials, and maintain quality control throughout the process is critical.

MYT Machining stands out as a dependable partner due to its technical depth, advanced CNC infrastructure, and commitment to precision manufacturing. With years of experience across industries, the MYT team supports projects from design review to final inspection. Their digital quoting system, real-time communication, and ability to handle challenging materials make them a go-to resource for manufacturers needing high-quality CNC components.

Final Thoughts: Precision Manufacturing Starts with the Right Knowledge and Partner

Understanding CNC machining goes beyond knowing how machines operate. It’s about recognizing its strategic role in accelerating innovation, improving quality, and reducing time-to-market. As industries continue to demand tighter tolerances and more complex components, CNC machining becomes a critical enabler for product success.

Working with a partner like MYT Machining ensures that you don’t just get parts — you get precision, reliability, and responsive service. Whether you're prototyping a new design or scaling full production, MYT offers the tools, experience, and expertise to bring your project to life with confidence.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness