Precision CNC Machine Spindles for High-Performance Machining

Gilman Precision designs and manufactures precision CNC machine spindles that deliver exceptional accuracy, reliability, and efficiency for a wide range of industrial machining applications. Built with advanced engineering expertise, these spindles are ideal for milling, grinding, drilling, and other complex manufacturing processes that demand smooth, repeatable motion. Each spindle is crafted to the highest standards, ensuring optimal performance, long service life, and seamless integration into CNC machines and automation systems.

High-Quality CNC Machine Spindles for Superior Accuracy

Engineered for Precision Machining

Gilman’s precision CNC machine spindles are engineered to meet the rigorous requirements of modern manufacturing. By combining high-speed capability with minimal runout and vibration, these spindles enhance machining accuracy and improve surface finishes on critical components.

Reliable Performance in Demanding Environments

Every spindle is built with durable materials, advanced bearing systems, and effective thermal management to ensure long-term reliability. These features make Gilman spindles suitable for a wide range of industries, including aerospace, automotive, medical device manufacturing, and industrial equipment production.

Types of Precision CNC Machine Spindles

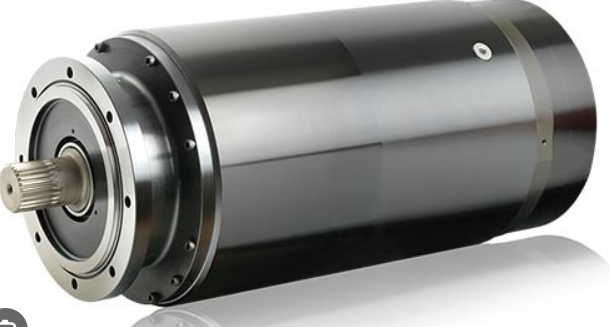

Motorized CNC Spindles

Motorized spindles integrate the motor directly into the spindle housing, creating a compact design ideal for high-speed applications. Gilman’s motorized spindles reduce vibration, improve balance, and increase machining efficiency by eliminating the need for external belt or gear drives.

Belt-Driven CNC Spindles

Belt-driven spindles offer flexibility in speed and torque configurations. Gilman’s precision CNC machine spindles with belt drives are designed for versatility, allowing users to adjust pulley ratios to suit different machining requirements while maintaining excellent accuracy.

High-Speed CNC Spindles

For applications that demand extreme speeds, high-speed spindles provide optimal performance with advanced bearing systems, cooling solutions, and balancing techniques. These spindles deliver smooth operation even at elevated RPMs, making them ideal for fine milling and precision grinding.

Key Features of Gilman Precision CNC Machine Spindles

Advanced Bearing Technology

Gilman spindles use precision bearings designed for high-load capacity and low friction. Proper preload and bearing selection reduce wear, increase rigidity, and improve spindle life even under continuous operation.

Superior Thermal Management

To maintain accuracy during extended machining cycles, Gilman incorporates cooling systems and thermal stabilization techniques that minimize heat buildup and thermal expansion.

Dynamic Balancing for Smooth Operation

Every spindle is dynamically balanced to reduce vibration, ensuring better cutting performance, longer tool life, and improved surface finishes.

Customizable Spindle Designs

Gilman offers customization options for speed, torque, mounting configurations, and tool interfaces, ensuring each spindle fits seamlessly into your CNC machine.

Benefits of Precision CNC Machine Spindles

Improved Machining Accuracy

By minimizing runout, vibration, and thermal distortion, Gilman’s precision CNC machine spindles enable tighter tolerances and more consistent part quality.

Longer Tool and Spindle Life

Smooth spindle operation reduces cutting forces and tool wear, extending the lifespan of both the spindle and cutting tools while lowering maintenance costs.

Higher Productivity

High-speed, reliable spindle performance shortens cycle times and increases machining throughput, improving overall productivity in manufacturing environments.

Versatile Applications

Gilman spindles are suitable for a variety of machining operations, from heavy-duty material removal to delicate finishing tasks, making them an excellent choice for diverse industries.

Applications of Precision CNC Machine Spindles

CNC Milling Machines

Gilman spindles enhance milling machine performance by providing stable, high-speed cutting for complex geometries and high-precision components.

CNC Grinding Machines

For precision grinding applications, these spindles deliver consistent rotational accuracy, ensuring superior surface finishes on hardened materials.

CNC Drilling Machines

In drilling applications, precision CNC machine spindles maintain optimal torque and speed, resulting in accurate hole placement and improved drill bit life.

Robotics and Automation Systems

Custom spindle designs integrate seamlessly into robotic arms and automated systems, enabling high-speed machining in automated production lines.

Customization Options for CNC Spindles

Speed and Torque Configuration

Gilman customizes spindle speed ranges and torque outputs to meet specific machining requirements, ensuring optimal cutting conditions for any material.

Tool Interface and Mounting

Custom tool holders, tapers, and mounting configurations allow for easy integration into existing CNC machines without major modifications.

Cooling and Lubrication Systems

Depending on the application, spindles can be equipped with air, oil-mist, or liquid cooling systems to maintain thermal stability during prolonged use.

Drive System Options

Whether you need a direct-drive motorized spindle or a belt-driven configuration, Gilman tailors each spindle design for the desired performance and machine compatibility.

Design and Manufacturing Excellence

Precision Engineering

Every precision CNC machine spindle is designed using advanced modeling software, ensuring optimal rigidity, balance, and thermal behavior for high-performance machining.

High-Quality Materials

Gilman uses premium materials for spindle shafts, housings, and bearings to ensure long-term durability and resistance to wear under heavy-duty conditions.

Rigorous Testing and Quality Control

Before delivery, each spindle undergoes extensive testing for vibration, runout, thermal stability, and load capacity. This ensures every spindle meets Gilman’s strict quality standards.

Maintenance and Support for CNC Spindles

Preventive Maintenance Programs

Gilman provides detailed maintenance guidelines to help customers extend the life of their spindles, prevent costly downtime, and maintain peak machining performance.

Repair and Rebuild Services

If a spindle requires service, Gilman offers professional spindle repair, rebuild, and refurbishment services to restore it to like-new condition.

Technical Support and Engineering Assistance

From installation to long-term operation, Gilman provides continuous technical support to ensure each spindle performs at its highest potential.

Industries That Rely on Gilman Precision CNC Machine Spindles

Aerospace Manufacturing

Aerospace components require extreme precision. Gilman spindles provide the stability and accuracy needed for machining complex aerospace parts.

Automotive Production

For high-volume automotive manufacturing, precision CNC machine spindles deliver reliable performance and consistent quality for engine, transmission, and chassis components.

Medical Device Manufacturing

In the medical industry, spindles support the production of intricate surgical tools, implants, and precision components with flawless accuracy.

Industrial Equipment and Tooling

Gilman spindles are widely used in heavy equipment manufacturing, mold making, and tooling applications where durability and accuracy are critical.

Why Choose Gilman Precision CNC Machine Spindles

Decades of Experience in Motion Control

With over 70 years of expertise, Gilman Precision is a trusted leader in spindle design and manufacturing, offering proven solutions for a variety of machining applications.

Superior Quality and Reliability

Every spindle is built to exceed industry standards, ensuring long-lasting performance even in the most demanding machining environments.

Customization for Any Application

Gilman works closely with customers to design and build spindles tailored to their unique requirements, providing maximum flexibility and efficiency.

Complete Lifecycle Support

From design and manufacturing to maintenance and repair, Gilman supports customers throughout the entire lifecycle of their spindle systems.

Achieve Exceptional Machining Performance with Precision CNC Machine Spindles

When machining accuracy, reliability, and productivity are essential, Gilman Precision provides precision CNC machine spindles engineered to meet the highest standards. Whether you need a high-speed motorized spindle for delicate milling or a robust belt-driven spindle for heavy-duty machining, Gilman delivers tailored solutions that enhance the performance of your CNC equipment.

With advanced design, premium materials, and rigorous testing, Gilman ensures every spindle delivers consistent results, long service life, and reduced downtime. Backed by decades of motion control expertise, Gilman Precision is your trusted partner for achieving superior machining performance in any industry.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness