The Rise of CAD Technology in Jewelry ***gn: A Game-Changer for Modern Craftsmanship

In the intricate world of jewelry ***gn, where detail, precision, and artistry are paramount, technology has carved a new path—reshaping how ***gners conceptualize, develop, and produce their creations. At the forefront of this digital revolution is CAD (Computer-Aided ***gn) technology, a powerful tool that has dramatically transformed the jewelry industry in recent years.

Traditionally, jewelry ***gn relied heavily on manual craftsmanship—hand-drawn sketches, wax carving, and metalworking. While these artis*** methods still hold their value in bespoke craftsmanship, they often fall short in terms of speed, accuracy, and scalability. CAD technology bridges this gap, allowing for the creation of highly detailed, customizable, and production-ready jewelry ***gns with greater efficiency.

In this article, we delve deep into the world of CAD technology, exploring how it works, its key advantages, and why it has become a cornerstone in modern jewelry ***gn.

What Is CAD Technology?

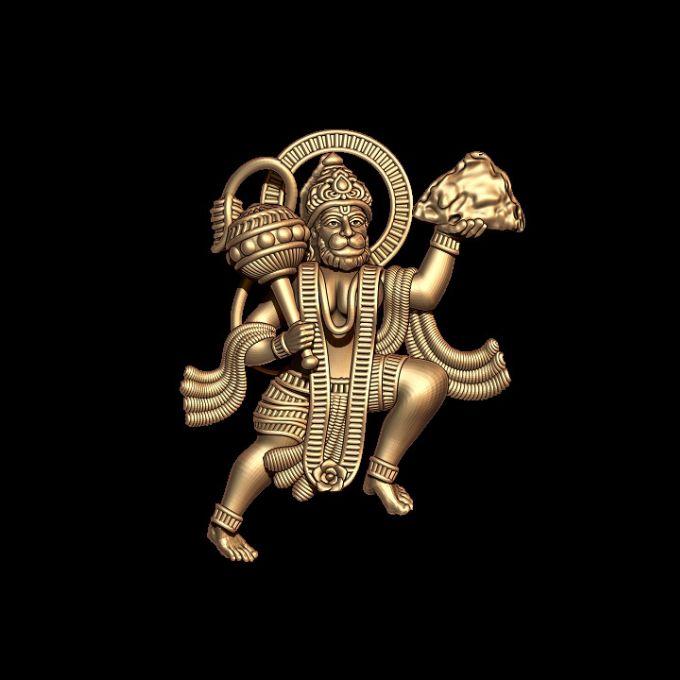

Computer-Aided ***gn (CAD) is a software-based technology that enables ***gners and engineers to create, modify, ***yze, and optimize ***gns digitally. In jewelry ***gn, CAD tools allow for the creation of 3D models of rings, pendants, bracelets, murtis, and other intricate pieces. These digital models can be viewed from any angle, altered with precision, and used to generate STL (Stereolithography) files—which are crucial for 3D printing or CNC machining.

CAD software ranges from general-purpose ***gn programs to those specifically tailored for jewelry, such as RhinoGold, MatrixGold, and JewelCAD. These platforms are equipped with specialized tools for gemstone settings, metal thickness control, surface texturing, and other jewelry-specific functions.

How CAD Technology Works in Jewelry ***gn

The CAD jewelry ***gn process typically unfolds in the following steps:

-

Conceptualization and ***gn

-

The ***gner begins with an idea or sketch and translates it into a digital form using CAD software. The 3D modeling environment allows for the creation of highly detailed and accurate representations of jewelry.

-

-

3D Visualization and Refinement

-

***gners can rotate, zoom, and inspect the 3D model to refine every element, including stone placement, prong height, surface finish, and symmetry.

-

-

File Conversion (STL Files)

-

Once finalized, the ***gn is exported as an STL file, a format that conveys precise 3D geometry. These files are essential for 3D printers and manufacturing machines.

-

-

Prototyping and Production

-

The STL file is used to produce a prototype (usually in wax or resin) via 3D printing. This prototype is then cast in metal using traditional lost-wax casting methods, or directly milled if using CNC technology.

-

Key Benefits of CAD Technology in Jewelry ***gn

1. Precision and Accuracy

One of the greatest advantages of CAD technology is the unmatched precision it brings to jewelry ***gn. Traditional hand-drawn sketches and wax carvings are subject to human error. In contrast, CAD allows ***gners to work with exact measurements, ensuring that every element—from stone settings to prong placements—is perfectly aligned and dimensionally consistent.

This level of accuracy is especially vital for complex pieces or when multiple components must fit together seamlessly, such as in hinged bracelets, articulated pendants, or modular rings.

2. Speed and Efficiency

CAD drastically reduces the time required to move from concept to prototype. What might take days or weeks with hand-drawn ***gns can now be accomplished in hours with CAD. ***gners can duplicate elements, apply symmetrical changes, and render multiple variations of a ***gn without starting from scratch.

Moreover, the ability to reuse ***gn templates or libraries streamlines the creation of product collections or custom variants, making it ideal for mass production or on-demand customization.

3. Customization and Client Collaboration

Today’s jewelry consumers increasingly ***re custom-made pieces that reflect their individual tastes and stories. CAD facilitates this by allowing for easy modification of existing ***gns. A ***gner can instantly change ring sizes, stone shapes, or engraving patterns based on customer preferences.

Additionally, CAD allows for visual renderings that clients can review before production. This visual confirmation reduces misunderstandings and builds trust, as clients can see a photorealistic version of their piece before it's made.

4. Reduced Waste and Cost Savings

Working digitally eliminates much of the trial-and-error inherent in manual ***gn. ***gners can detect and correct potential ***gn flaws before production, reducing wasted materials and costly remakes. With STL files, only approved ***gns move to 3D printing and casting, saving both time and precious resources like gold or platinum.

This optimization not only improves sustainability but also makes CAD an economical choice for both independent artisans and large-scale manufacturers.

5. Scalability in Production

For jewelry businesses that manufacture multiple pieces or product lines, CAD provides a scalable solution. Once a ***gn is approved, it can be duplicated, resized, or adapted for different metals or gemstones without extensive manual labor. This digital repeatability supports consistent quality control across batches and simplifies inventory management.

6. Prototyping and Innovation

CAD technology integrates seamlessly with 3D printing, enabling rapid prototyping. ***gners can test form, fit, and aesthetics by printing prototypes in wax or resin. These models allow for tangible review and real-world testing before proceeding to final production.

Moreover, CAD opens the door for innovation and experimentation. ***gners can explore new shapes, complex geometries, and organic forms that would be nearly impossible with traditional techniques. This creative freedom has led to the emergence of bold, modern jewelry trends and intricate detailing that define today’s high-end pieces.

7. Remote Collaboration and Global Access

CAD files can be shared digitally across the globe, enabling collaboration between ***gners, manufacturers, clients, and vendors in real time. This capability is particularly valuable in an increasingly globalized market, where ***gn and production teams might be located in different countries.

Remote approvals, quick revisions, and seamless communication have made CAD an essential tool in modern jewelry project management.

The Future of Jewelry ***gn with CAD

As CAD software continues to evolve, we can expect even more integration with AI-assisted ***gn, parametric modeling, and augmented reality (AR) tools. These advancements will enable dynamic, real-time customization for customers—allowing them to visualize and modify jewelry on-screen or even via mobile apps before purchase.

Moreover, with growing interest in virtual jewelry try-ons, digital showrooms, and NFT-based jewelry ***gns, CAD will play a foundational role in bridging traditional craftsmanship with future-forward retail and digital experiences.

Final Thoughts

The integration of CAD technology into jewelry ***gn has fundamentally reshaped the industry. By combining artistic vision with digital precision, CAD offers a powerful platform for innovation, efficiency, and creative expression.

From enabling custom ***gns and reducing waste to accelerating production and ensuring flawless accuracy, CAD has become indispensable in the world of fine jewelry. As ***gners and manufacturers continue to adopt this technology, the jewelry industry is poised to enter a new era—where tradition meets technology and creativity knows no bounds.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness